- Henan Doing Machanical Equipment Co.,Ltd

-

Zhengzhou, Henan, China

- Main products: cassava machinery, gluten making machine, gluten washing machine, glucose syrup manufactuering plant, fructose syrup processing machine, cassava starch processing machinery, cassava flour making machine, garri making machine

-

Elina

Hi there! Welcome to my shop. Let me know if you have any questions.

Elina

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

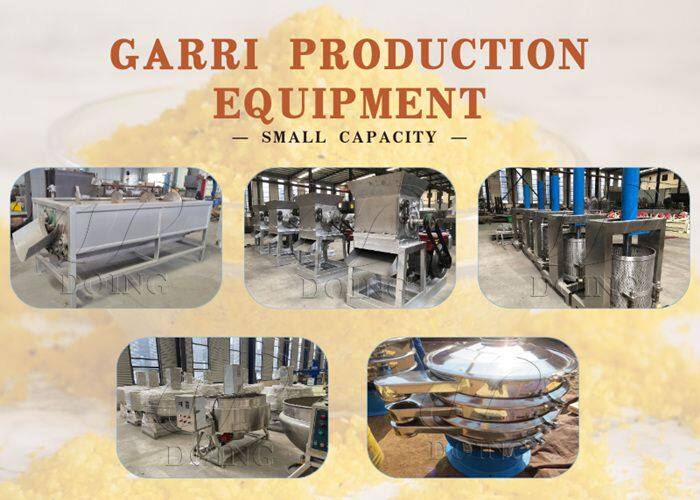

Introduction of small scale garri processing plant with capacity of 0.5~2 tons/hour

2025-10-14 17:19:07

Garri is popular in Africa because it is cheap and can be used as a substitute for wheat flour. As a leading cassava deep processing machine manufacturer in China, Henan Jinrui has three garri processing plant equipped with different output machines. That is small scale garri processing plant(0.5~2 tons/hour), medium scale processing plant(3~6 tons/hour) and large scale processing plant(2~8 tons/hour). Small garri processing plant mainly includes cassava peeling machine, cassava grating machine, dewatering machine, garri fryer and sieving machine, which has low investment costs and can recover profits in a short time.

Watch a flow chart to understand small scale garri processing plant

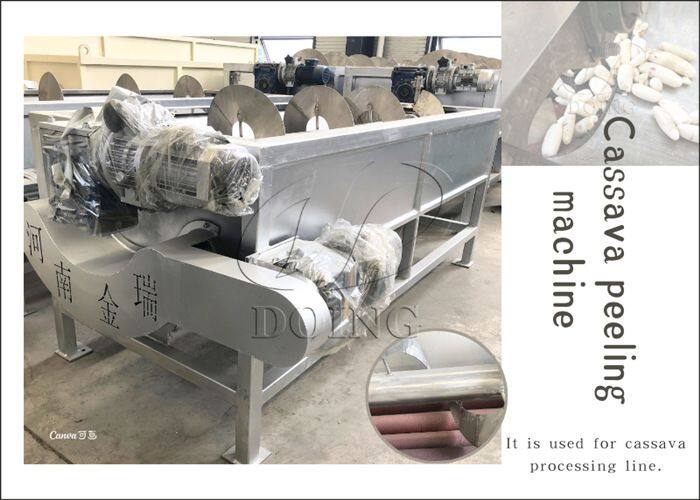

Steps 1: Peel and wash cassava tubers

Peel the fresh cassava tubers with cassava peeling machine. This step ensures the quality of the finished product because the cassava skin contains toxic substances and cannot be eaten. Considering the inefficiency and low peeling rate of manual peeling, the use of peeling machine can greatly save labour cost and increase productivity.

Steps 2: Grate cassava tubers into mash and wait for fermentation

While the machine is running, load the washed and peeled cassava tubers into a cassava grater and crush the tubers into a pulp. The broken cassava is bagged and fermented for 2-3 days, which helps to increase the garri flavor and obtain a better taste.

Steps 3: Dewater cassava pulp

This step will use hydraulic press machine. The hydraulic press uses the pricinple of hydraulic press to directly squeeze the water out of the starch milk water and then discharge it. Put bags into hydraulic press machine for dewatering, after which we can get cassava cake with moisture content less than 40%.

Steps 4: Fry the wet garri

Next is the to fry garri. Traditional small scale garri processing plant normally use an old type pan with firewood heating and people operate it all the time, which is more and more inconvenient to use. The garri fryer produced by Henan Jinrui can automatically stir fry and control the temperature by itself, which ensures that no gelatinization occurs during the frying process of garri. The garri wok has 3 heating methods to choose from, namely gas heating, oil heating and electric heating. You can choose the most cost-effective one according to the local market economy.

Steps 5: Sieve the finished garri and pack it for sale

Last, use a vibration sieve to screen out the finished garri that meets the particle size requirements, and then pack them into bags for sale to the market.

If you want to know more about garri processing machine and price, feel free to contact us, we have professional staff to answer your questions. Trust me, Henan Jinrui won't let you down.

Tags: small scale garri processing plant, 0.5-2TPH garri processing machine, Henan Jinrui garri processing machine